RELIABILITY FORMULA FOR TURBOMACHINERY

LLC John Crane – Iskra has been successfully operating in turbomachinery equipment market in Russia for over 19 years.

The Company is the only official representative of John Crane in dry gas seals sector within the territory of Russia and Belarus with exclusivity for DGS servicing and refurbishment in compliance with the highest global quality standards.

up to day.

-

Foundation of LLC John Crane – Iskra.

-

Commissioning of DGS test rig.

-

Commencement of in-house production of DGS control panels.

-

Over 1000 John Crane seals supplied.

-

Launch of production localization program.

-

Commencement of own manufacture of couplings and filters.

-

Commissioning of mechanical area.

-

Renovation of the production building (1195 m²).

Launch of new seal type - Aura™. -

Commissioning of faces lapping and polishing area.

-

Extension of mechanical area by means of CNC machines mounting.

Commissioning of laser measuring units.

Upgrade of test rig. -

INTERGAZSERT certificate for QMS has been obtained.

Conclusion of Ministry of Industry and Trade of the Russian Federation confirming production of DGS, CP and gas filters in Russia has been received.

The second welding station has been arranged, storage area has been expanded. -

Designing, construction and commissioning of own electric power substation have been conducted.

Outfitting of piping systems production area has been completed.

Statement of Ministry of Industry and Trade of the Russian Federation approving production of DGS, CP, couplings and gas filters in Russia has been obtained. -

Arrangement of a special room for inspection purposes: dye penetration inspection, hardness measurements.

Putting into service of a coating room.

Renewal of machine pool of machining department.

Commencement of construction of a new building with production and administrative premises.

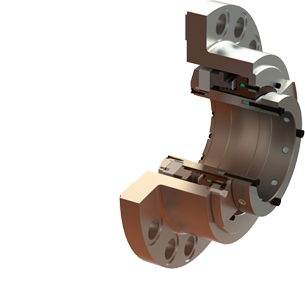

Manufacturing capacity

For today capital repair of the additional production building with total area of 1195m² has been performed within the framework of the Company's development strategy.

Throughout its activities, LLC John Crane – Iskra has been pursuing a systematic policy of localization and development of equipment production in the Russian Federation. At the moment, the level of production localization has been confirmed by the Ministry of Industry and Trade of Russian Federation. At the same time, all products manufactured by LLC John Crane – Iskra comply with the high international standards adopted by John Crane.

When fulfilling the program of production development LLC John Crane – Iskra is striving for manufacturing high-quality Russian-made products at fair and economical price, which can be competitive both in domestic and foreign markets.

Mechanical area

Quality control area

Welding production

Balancing area

Oven and seal head test rig for polymers heating and fitting

Control panels assembling and testing area

Measuring unit

Faces lapping and polishing area

Test rig for seals dynamic testing

Large stock of products spare parts

Advantages

What do you obtain having cooperation with us?

Reduced expenses associated with refurbishment and operation

Reduced amount of unscheduled shutdowns

Manufacture and service center on the territory of Russia

Compliance with global quality standards

Experienced maintenance staff

Improved environment safety

Performance indicators dynamics

Geography of sales and servicing of LLC John Crane – Iskra is very broad. Customers from more than 80 cities and towns of Russia and Belarus are a part of the clients list.

Leading compressors manufacturers from Perm, Kazan and Saint-Petersburg are among repeat customers. One of the key accounts is PAO Gazprom, including lots of its subsidiaries. Recently LLC John Crane – Iskra has been working on establishing and strengthening close relationships with chemical and petrochemical enterprises as well as companies of Russian power sector.