Products

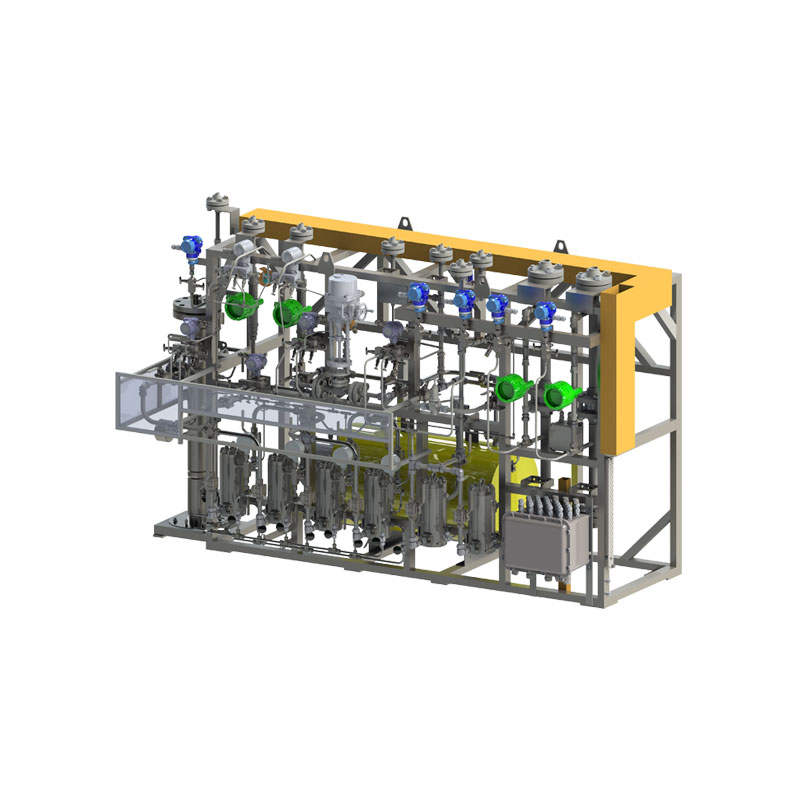

Range of equipmentDGS control panel

Control panel is a unit that provides conditions for dry gas seals operation. In other words by means of it gas is supplied to certain seal cavities as well as air or Nitrogen with required parameters. These actions are necessary for correct and reliable operation of dry gas seals.

As a rule, DGS control panels are designed particularly for each compressor type. Very often standard compressors with changeable bundles for different compression rates are designed. In this case similar panels with various instruments ranges can be used.

Basic systems

Operation principles

Flow control

For example, several control panels with the above mentioned control philosophy have been supplied for ООО Astrakhan gazprom (Astrakhan GPP). Retrofits of Creusot Loire RD7B, RINA CKD 5RSA 39 and 5TsD 208/30-45М compressors involving replacement of oil seals with dry gas ones have been executed. In total, seven machines have been retrofitted against the project.

Pressure control

By application these are mainly line compressor stations and underground gas storages (UGS).

Design standardization and possibility to equip panels with transmitters and instruments for a specific compressor type lead to its application for NTs-12S/56, NTs16S/56 compressors series.

Technical parameters of DGS control panels shall be selected based on DGS operation features as well as on customer's requirements. When necessary or following technical requirements to equipment DGS control panel can be additionally equipped, for instance, with gas heater, system of gas prefiltration/ separation (seal gas as well as barrier gas) and with other equipment and systems.

DGS control panels with Nitrogen supply systems for Т83/Т93FR barrier seals.

In comparison with the standard control panel design this one has additional system of technical air treatment and system of Nitrogen generation of compressed air. The peculiarity of this system is the use of advanced technologies for compressed air separation and Nitrogen generation.

The advantage of this panel is that Nitrogen treatment and generation system is mounted on the same frame with seal gas supply system and DGS control system. This helps to eliminate the use of additional piping between DGS system and Nitrogen generation system and reduce the system size and cost.

This product is available in the markets of Russia, Belarus and Ukraine